| |

|

|

BY PHONE

(631) 249-5566

BY EMAIL

BY Web

|

|

| |

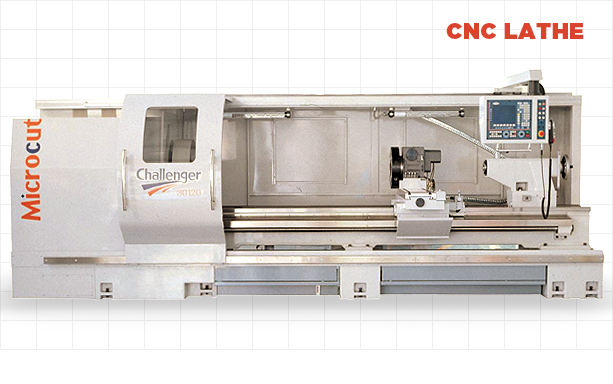

Main Features:

- Fanuc OITD CNC Control

- High rigidity and precision of manufacturing

- High efficiency output

- Hardened & ground bed ways

- Automatic lubrication system

- Fine surface finish of machined work piece

- Extremely wide bed

- Chip conveyor available if request

- Wide selection of spindle bore

- C axis & power turret on request

Specifications:

|

| Item |

Standard |

Metric |

| Swing in gap |

45.27” |

1150mm |

| Swing over bed |

33.85” |

860mm |

| Swing over cross slide |

20.47” |

550mm |

| Max. cutting length |

39.37”/78.74”/118.11”/157.48”/

196.85”/236.22” |

1000/2000/3000/4000/

5000/6000mm |

| X axis travel |

17.91” |

455mm |

| Z axis travel |

47.24”/86.61”/125.98”/165.35”/

204.72/244.09” |

1200/2200/3200/4200/

5200/6200mm |

| Rapid traverse (X & Z) |

393.70”/min & 472.44”/min |

10M/min & 12M/min |

| Spindle bore |

4.17”(std.)/ 6.02”, 9.05”, 10.00”,

13.97” (opt.) |

106mm(std.)/153, 230, 254,

355mm (opt.) |

| Spindle speed |

15-1480rpm (4.17”/6.02”)/

10-750rpm (9.05”/10.00”)/

10-500rpm (13.97”) |

15-1480rpm (106/153mm)/

10-750rpm(230/254mm)/

10-500rpm (355mm) |

| Main power |

29.50/44.25 hp |

22kw/33 kw |

|

* Specifications are subject to change without notice.

Standard Accessories:

- Fanuc OITD CNC Control

- 4.17" spindle bore

- Main spindle motor

- Automatic speed changer

- Chuck sliding guard with interlock device

- Gap bed

- Tailstock

- Traveling front single door with interlock safety device

- Coolant system

- Lubrication system

- Low voltage circuit system

- Protable MPG

- CE Norms

- Leveling pads

- Operation manual & parts list (in English)

- Tool set & kits

|

Optional Accessories:

- Fagor and Siemens Controls available

- Enlarged 6.02"/9.05"/10.00"/13.97" spindle bore

- TB-200 V8/VDI50 turret, brand Baruffaldi

- LS-200 8 station hyd. turret

- Hyd. 4 way tool post

- Boring bar base/holder

- TBMA-200 V8/VDI50 power turret, brand Baruffaldi

- C axis

- Rear chuck mounting preparation

- Rear chuck guard

- Manual 3-jaw chuck

- Hyd. 3-jaw chuck

- Automatic bar feeder

- Roller steady rest 1.96"-11.81"

- Roller steady rest 9.84"-16.53" for BNC-3000 series

- Roller steady rest 9.84"-19.68" for BNC-3500/4000 series

- Hydraulic steady rest preparation

- Follow rest .78"-7.87"

- Hyd. tailstock quill

- Rotating tailstock quill

- Tailstock end cover with limit switch (for 39.3"~157.48" length only)

- Full enclosure guarding for 40"/80"/120"/160" length.

- Chip conveyor + wash down system

- Air conditioner for electric cabinet

- Heat exchanger for electric cabinet

- EMC

- Transformer for other than 220V

- Tool holders

- Fanuc 0iTC with 10.4" LCD display and manual guide i

|

|